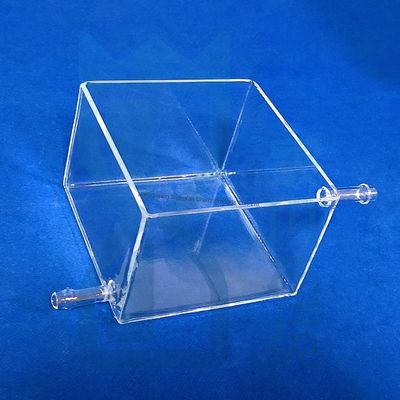

An alumina crucible is a high-temperature vessel made from aluminum oxide (alumina) known for its exceptional thermal stability, chemical inertness, and resistance to corrosion. These properties make them ideal for applications in melting, calcination, sintering, and high-temperature chemical reactions across industries like ceramics, glass, and metals. They are especially valuable in analytical chemistry for sample preparation to ensure contamination-free results.

Applications

High-Temperature Processes: Used for melting, calcination, and sintering in the production of ceramics, glass, and metals.

Sample Preparation: In analytical chemistry, they serve as ideal vessels for sample preparation and high-temperature reactions, preventing contamination.

Material Handling: Due to their dimensional stability, they are used for precise temperature control and material handling in various industrial applications.

Semiconductor Industry: Utilized in making parts for semiconductor manufacturing, including CVD (chemical vapor deposition) and ion implants.

Chemical Industry: Employed for various chemical processes, including use as industrial furnace materials and for protecting high-temperature thermocouples.

Important Considerations

Heating and Cooling Rates: To extend their service life and prevent damage, alumina crucibles should be heated and cooled slowly.

Material Compatibility: It's important to avoid chemical reactions with the crucible material, especially at high temperatures. They may also have limited compatibility with certain molten metals like iron, nickel, and copper at high temperatures.

Prohibitions for the use of alumina crucibles:

Alumina crucible: Although it is resistant to high temperatures, not all substances can be heated in it.

First, in terms of chemical properties:

Alumina is a binary oxide that is afraid of both strong acids and strong bases. Specifically, when strong bases such as sodium hydroxide and potassium hydroxide are heated, they will react with the crucible to form alumates. What needs to be avoided is

also the alkali metal oxides and hydroxides. Additionally, there are several special compounds that require special attention, such as sodium thiosulfate, which is a sulfur-containing compound, and phosphorus-containing compounds that will corrode the crucible at high temperatures. Heavy metal salts are also not allowed, such as lead salts, mercury salts, and copper salts, etc., all of which should be avoided.

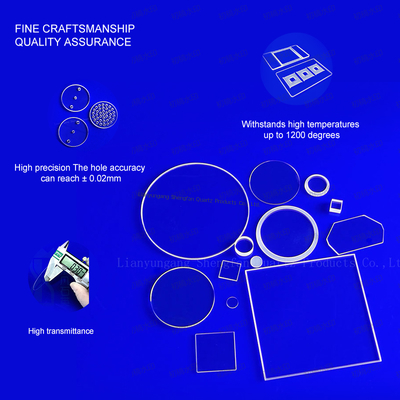

Apart from chemical substances, the physical limitations during use are also very important. The long-term usage temperature of an alumina crucible should not exceed 1200 degrees Celsius. Moreover, direct heating with an open flame should be avoided. During operation, handle the crucible gently and keep it clean to ensure uniform heating. Remember these points, and you can use the alumina crucible safely.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!