UV curing technology has emerged as a core process in green manufacturing across the printing and packaging, electronics manufacturing, new energy and other industries, thanks to its advantages of instant curing, zero VOC emissions, and high productivity. Within the UV curing system, a seemingly inconspicuous quartz plate serves as the invisible gatekeeper that determines curing efficiency, product quality, and equipment service life.

At the heart of UV curing is the excitation of photoinitiators by ultraviolet light of specific wavelengths (UVA/UVB/UVV/UVC), triggering the rapid cross-linking and film formation of prepolymers and monomers. This process imposes extremely high requirements on the precise transmission of light: it must ensure the efficient penetration of UV energy, block thermal damage caused by infrared radiation (IR), and prevent dust and ink from contaminating the light source. Ordinary glass, with its low UV transmittance and susceptibility to heat absorption and deformation, fails to meet these requirements, whereas high-purity quartz plates (SiO₂ ≥ 99.99%) perfectly resolve this pain point.

Advantages of Quartz Plates:

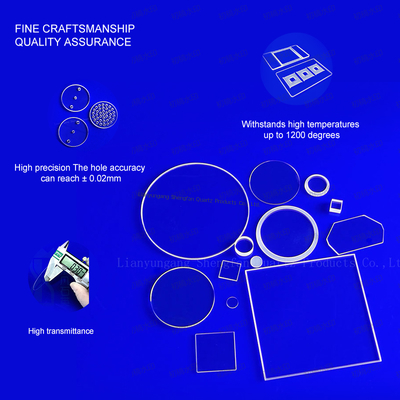

Ultra-high UV Transmittance: After precision polishing, quartz plates achieve a transmittance of 90%-94% in the UVA/UVB/UVV bands and 85%-90% in the UVC band, with virtually no UV energy loss. This guarantees uniform and fast curing, significantly boosting the productivity of assembly lines.

Efficient Infrared Radiation Filtration: Quartz plates can effectively filter out the IR thermal radiation accompanying UV light sources, preventing deformation and yellowing of heat-sensitive substrates such as plastics, films, and flexible printed circuits. At the same time, they protect UV lamps and equipment components, extending their service life.

High Temperature Resistance + Low Expansion + Corrosion Resistance: Quartz plates feature an extremely low coefficient of thermal expansion, maintaining stable dimensions and optical properties under the high-temperature, high-frequency operating conditions of UV curing equipment. Their smooth, defect-free surface not only avoids light refraction distortion but also blocks contaminants from entering the light source, reducing equipment maintenance frequency.

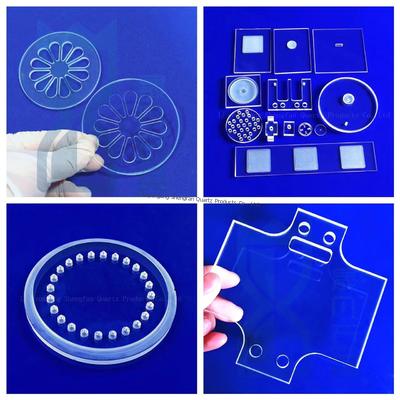

Application ,from Printing to Semiconductors:

Printing and Packaging: For UV ink curing, delivering vibrant colors, strong adhesion, and instant drying, with printing speeds increased by over 30%.

Electronics Manufacturing: For UV adhesive curing of PCBs and semiconductor chips, enabling precise light control to ensure the quality of precision solder joints and encapsulation, with no residual adhesive and no thermal damage.

New Energy: For the curing of solar window films and photovoltaic module encapsulants, providing thermal insulation and temperature control to safeguard the optical performance and service life of products.

High-end Manufacturing: For UV curing in optical instruments and biomedical consumables, where the high purity and stability of quartz plates meet the demands of precision production.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!